-

Environmentally Sealed SWs

Ideal for equipment used outdoors Rocker SW & Toggle SW ELW / ETW -

Suitable for high vacuum or

high temp. or high pressure range Thin-film Pressure Sensors Product Lineup -

Quick and accurate detection,

Compatible with corrosive liquids Leakage Sensor WL10 -

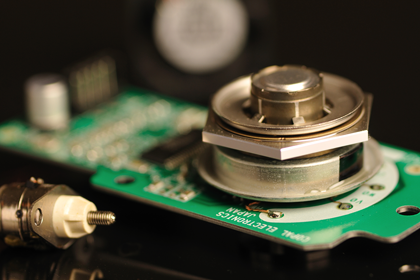

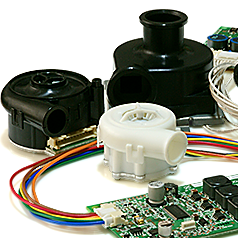

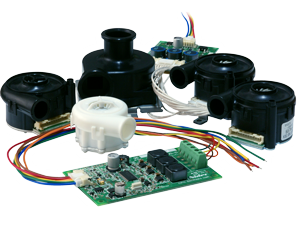

Compact but high power!

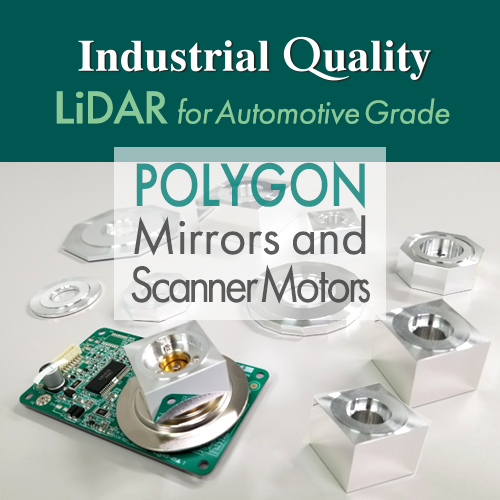

Long life, Low vibration Aerodynamic Bearings Micro Blowers

-

Rocker Switch & Toggle SwitchELW / ETWCompact and high capacity 15 A. Environmentally Sealed SWsSwitches. Ideal for equipment used outdoors.

-

Quick & Accurate DetectionLeakage Sensor WL10Available Compatible with corrosive liquids by PFA-housing. Without reflection control plate or additional Amp.

-

Thin-film Pressure SensorsProduct LineupSuitable for high vacuum or high temperature or high pressure range.

-

Micro BlowersTF seriesAerodynamic bearings technology realizes long life and low vibration, small size compact but high power.

-

2023/12/28

[New!] Environmentally sealed IP 67 rated ELW Rocker & ETW Toggle switches

-

2023/03/31

Completed the acquisition of all the shares of Midori Precisions Co., Ltd.

-

2023/03/15

Executed a stock transfer agreement on the acquisition of Midori Precisions Co., Ltd.

-

2023/02/01

Notification of Company Name Change (Effective 1 April)

-

2020/06/01

New Product Lineup Announcement:High precision pressure switch "PS97 series" for middle-high pressure