Liquid Leak Sensors Special Feature

Liquid Leak Sensos Special Feature

Introduction

Leaks from pipes, condensation, and flooding can cause damage to equipment and facilities, while hazardous chemical leaks pose risks of accidents and disasters. Such environments are not uncommon in various industries. The role of a liquid leak sensor is to quickly detect these dangers and prevent them before they occur.

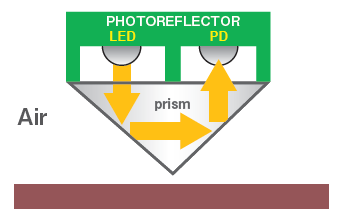

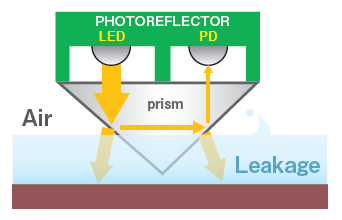

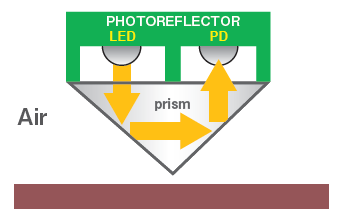

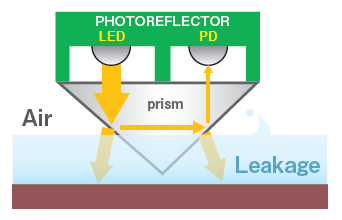

Our liquid leak sensor WL10 series is an optical spot-type sensor utilizing infrared reflection. The detection mechanism consists of a light-emitting diode (LED) and a photodiode (PD) inside the sensor. Light emitted from the LED is reflected by a prism and received by the PD, where it is converted into an electrical current. When liquid comes into contact with the prism, the light transmits through the liquid, significantly reducing the amount of light reaching the PD. This phenomenon is used to detect leaks.

-

Normal condition (No leak)

-

Leak

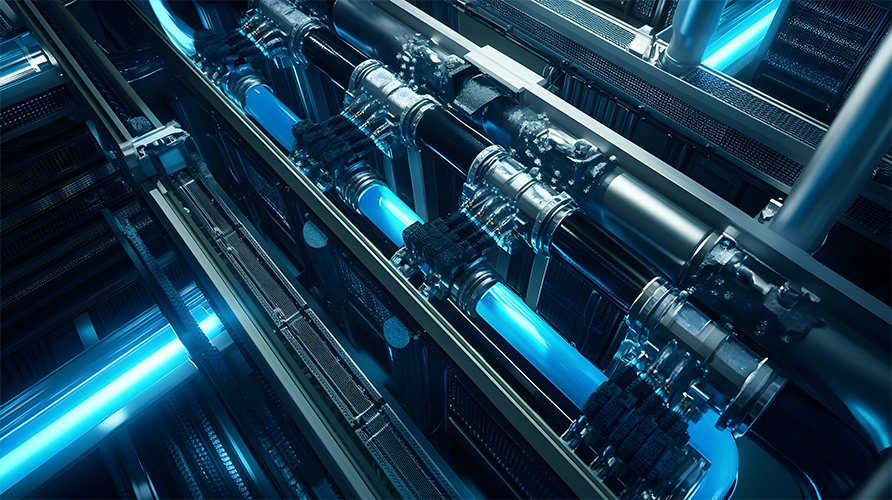

Various Applications

WL10 series is widely adopted in industrial applications, including:

1. Semiconductor Production EquipmentSPE

(e.g. CVD)

Assembly & testing

process (Dicing)

2. Water-cooled Servers

3. Chillers

4. Energy Storage SystemsESS

For detecting coolant leaks

in internal cells

5. Gas Welding Machines

6. Printing and Dyeing Machines

7. Medical Devices

Additionally, it is recommended for consumer applications such as:

8. White Goods, Kitchen, Sanitary EquipmentEQ

Key Advantages of WL10

Our WL10 series boasts the following features and advantages as:

1. Compact & Thin design

Enables pinpoint installation in narrow spaces.

2. Unique Advanced Optical Technology

3. No Need for a Shade-plateWithout Non Shade-plate

-

Typical leak sensor

-

WL10

Typical leak sensor

WL10

In environments with strong ambient light, such as mirror-finished floors, conventional leak sensors may fail due to excessive light received by the PD. However, our WL10 utilizes unique advanced optical technologies to minimize the effects of diffuse reflection, significantly reducing location constraints.

Typically, a "shade plate" is used beneath leak detection sensors to control excessive light interference. However, the WL10 does not require this, eliminating the risk of undetected leaks caused by liquid surface tension preventing it from passing over the plate.

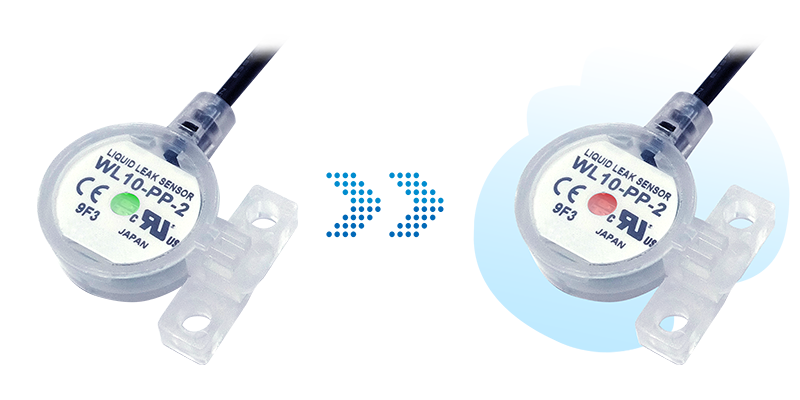

4. Without an external AmplifierAmp.

No amplifier is required, so ready to use. Under normal conditions, the switch output remains ON, and the LED lights up green. When a leak is detected, the switch output turns OFF, and the LED changes to red.

5. High Sensitivity & Fast Response

Detects leaks instantly. Check out the video bellow to see the high performance of the WL10.

6. PFA casing model available

Suitable for use with water and other corrosive liquid media.

7. IP67 structure

Waterproof and Dustproof with IP67.

8. RoHS compliant, UL and UL, CE certified

RoHS compliant, cULus recognized and CE/UKCA mark certified.

FAQ

◆ WL10 reusability

-

A WL10 detected a water leak. Can it be reused if the water is wiped off from its detection face?

-

Yes, it can. Wipe off the water droplets completely with a dry cloth. Failure to comply may result in a malfunction.

Considering the WL10 series leakage sensor, please feel free to contact us via the button below. Welcome inquiries regarding product suitability for your specific applications too.