Pushbutton switch CFPA

- ●To make a purchase, contact Distributors, or use e-commerce below.

SALES CHANNEL ;Check our Distributors.- SALES CHANNELClick here to check our Distributors.

Surface Mount Pushbutton Switches

- Compatible with Refl ow Soldering

- Washable

- Gold-Plated Contacts for Low Current Application

- Clip Contact Mechanism for High Contact Reliability

Specifications

| Rating Max. | 0.4VA( 28VDC max.)(Resistive load) |

|---|---|

| Rating Min. | 1μA 20mVDC (Resistive load) |

| Initial contact resistance | 80mΩ max.(1.5mA 1kHz 20mV min.) |

| Dielectric strength | 500VAC 1 minute |

| Initial insulation resistance | 500MΩ min. (500VDC) |

| Stroke | 1.1mm |

| Operating force | 1.5N±1N |

| Electrical life | 50,000 operations at max. rating |

| Switch timing | Non-shorting |

| Operating temperature range | -40℃~+80℃ |

| Storage temperature range | -40℃~+80℃ |

Part Numbering

| CFPA - | 1 | F | B4 - | A | 2 | T |

|---|---|---|---|---|---|---|

|

Series code & Acutuator P:Pushbutton |

Poles 1: 1 bit |

Switching function F: ONー(ON) |

Terminal B4: Gull wing R/A |

Actuattor shape A: standard |

Contact material 2: Gold plated |

Packaging specifications T:Taping |

List of part numbers

| Part number | Poles | Switching function | Terminal | Contact material | Packaging specifications | CAD |

|---|---|---|---|---|---|---|

| CFPA-1FB4-A2T | 1 bit | ONー(ON) | Gull wing R/A | Gold plated | Taping | |

| CFPA-1FB4-A2W | 1 bit | ONー(ON) | Gull wing R/A | Gold plated | Tray |

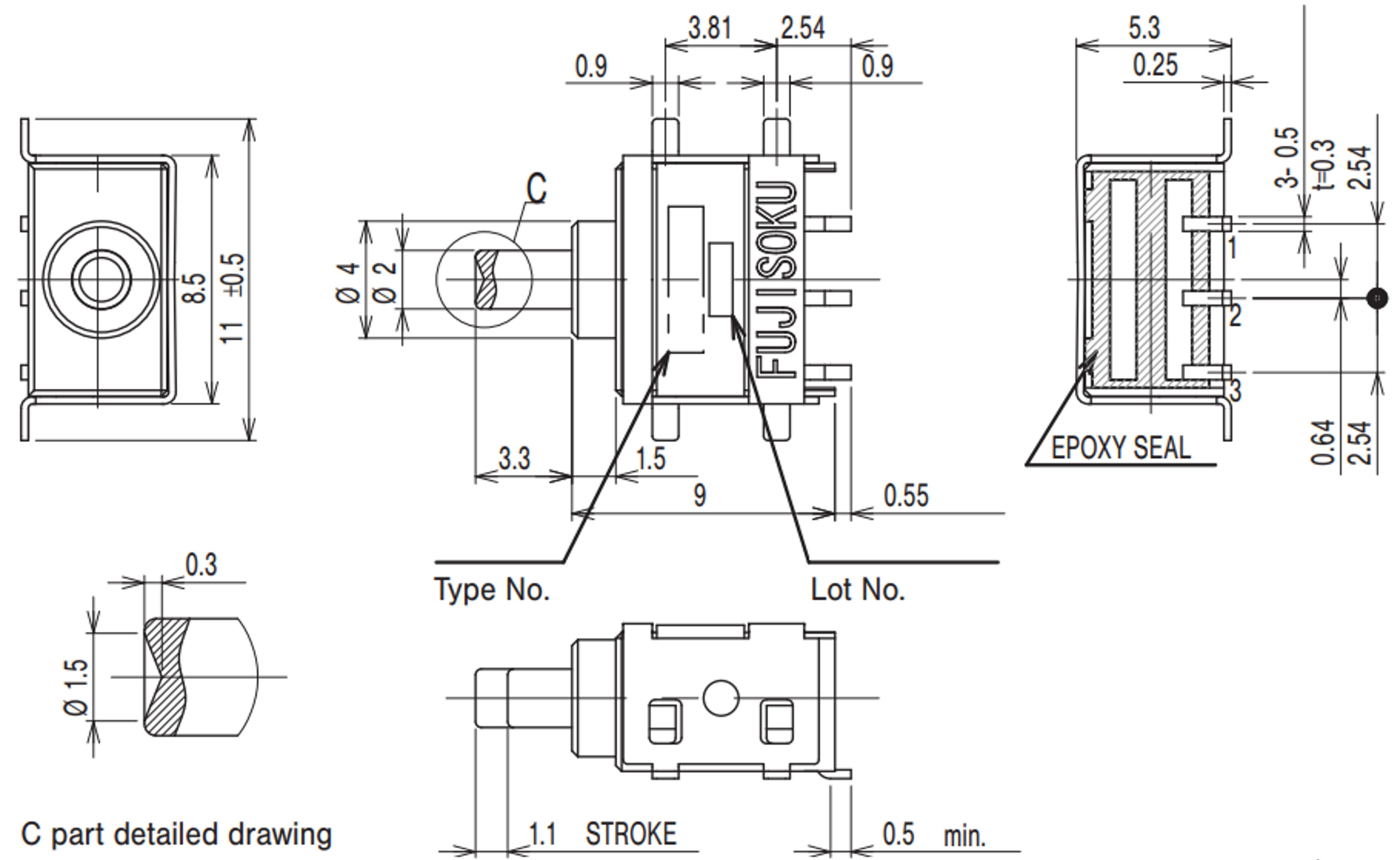

Outline Dimensions

(Unit:mm)

Switching function

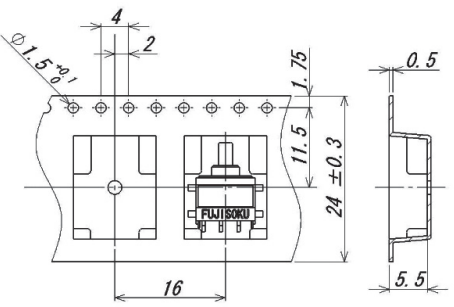

Pad Layouts

Soldering Specifications

(1)Reflow Soldering

Apply reflow soldering: 2 times max.

(2)Manual Soldering

Device : Soldering iron

350℃, Max.; 3-4 seconds, Max.

Flux Cleaning

- For the solvent, use water or alcohol. In addition, pay careful attention to use the solvent.

- The cleaning method is limited to immersion cleaning only. The cleaning time is 2 minutes, max, but be sure to minimize the time as

much as possible. - To clean the switch after soldering, wait until the switch temperature has cooled down to room temperature (30℃ or below).

- The product must be dried suffi ciently after cleaning. Improper drying may result in fl uctuation in torque or electrical damage.

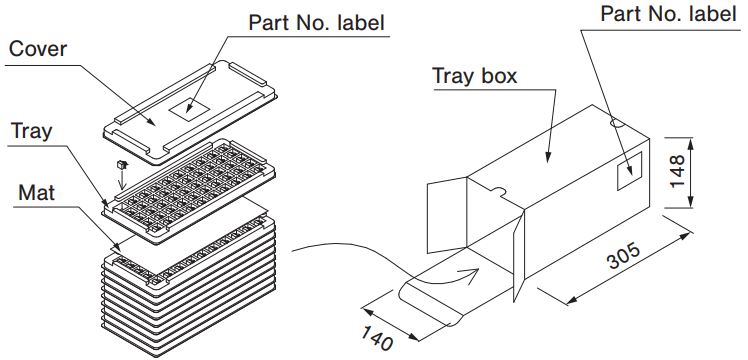

Packaging Specifications

-

●Taping (500 pcs /reel)

-

●Tray (50 pcs /tray)

Documents

Environmental Certificate

- ●The above contents and descriptions are subject to change without notice.