Rotary selector switch CS-4

-

CS-4

-

CS-4

Miniature Surface Mount Rotary Selector SW with Sealed Construction

- Optimum for high density board mounting applications

- Compatible with reflow and wave soldering

- Compatible with most automatic pick & place machinery

(J-hook and Gull wing types only) - Protection against dust and washable after soldering

- Excellent reliability due to precious metal contact

- In this series, material data sheets ideal for REACH-SVHC

surveys etc. can be downloaded in chemSHERPA-AI format. - Download chemSHERPA-AI from the list of P/N below

Standard Specifications

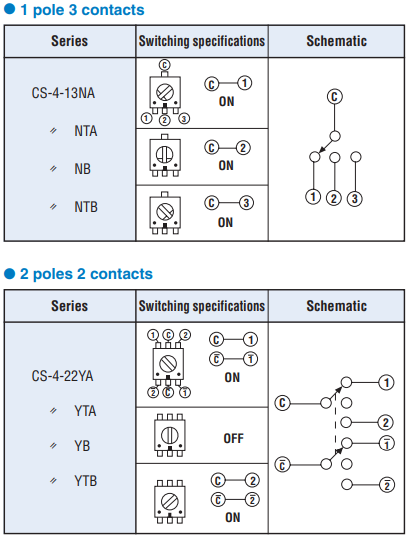

| Circuit type | 1 pole 2 contacts 1 pole 3 contacts 1 pole 4 contacts 2 poles 2 contacts |

|---|---|

| Operating temperature range | - 25 ~ 70 °C |

| Storage temperature range | - 40 ~ 70 °C |

| Sealing | Washable by “O” ring |

| Net weight | Approx. 0.08 g (CS-4-12, CS-4-13) Approx. 0.1 g (CS-4-14, CS-4-22) |

Electrical Characteristics

| Rating | Contact rating: 0.5 VA Maximum current: 100 mA Minimum current: 1 μA Maximum voltage: 16 V Minimum voltage: 20 mV |

|---|---|

| Contact timing | Non-shorting |

| Contact resistance | 100 mΩ maximum |

| Insulation resistance | 100 MΩ (500 VDC) minimum |

| Dielectric strength | 500 VAC, 60 s |

Mechanical Characteristics

| Stopper strength | 25 mN·m {255 gf·cm} minimum |

|---|---|

| No. of positions | 2, 3, 4 |

| Adjustment torque | 10 mN·m {102 gf·cm} maximum |

| Stepping angle | 45°, 90° (CS-4-12X only) |

| Solderability | 245 ± 3 °C, 2 ~ 3 s |

| Soldering heat | Flow: 260 ± 3 °C as the temperature in a pot of molten solder, immersion from head of terminal to backside of board, 5 ~ 6 s, two times maximum Reflow: Peak temperature 255 °C (Please refer to the profile below.) Manual soldering: 350 ± 10 °C, 3 ~ 4 s |

| Shear (Adhesion) | 5 N {0.51 kgf}, 10 s |

| Substrate bending | Width 90 mm, bend 3 mm, 5 s, 1 time |

| Pull-off strength | 5 N {0.51 kgf}, 10 s |

Environmental Characteristics

| Load life | 200 cycles minimum, 30 mA 16 VDC |

|---|---|

| Vibration | Amplitude 1.5 mm or Acceleration 98 m/s2,10-500-10 Hz, 3 directions for 2 h each |

| Shock | 490 m/s2, 11 ms 6 directions for 3 times each |

| Humidity (Steady state) | 40 °C, Relative humidity 90 ~ 95 %, 48 h |

| High temperature exposure | 70 °C, 16 h |

| Low temperature exposure | - 40 °C, 16 h |

| Thermal shock | - 40 (0.5 h) ~ 70 °C (0.5 h), 5 cycles |

Part Number Designation

| CS-4 | - | 1 | 3 | N | T | A |

|---|---|---|---|---|---|---|

|

Series name |

|

No. of poles 1:

1 pole

2:

2 poles

|

No. of contacts 2:

2 contacts

3:

3 contacts

4:

4 contacts

|

Contact timing (Circuit) N:

Non-shorting (SPDT, SP3P)

Y:

Non-shorting with neutral detent (SPDT, 2PDT)

X:

Non-shorting without neutral detent (SPDT)

|

Packaging form T:

Taping (Reel)

Blank:

Bulk in plastic bag

|

Shape of terminal A:

j-hook

B:

Gull·wing

C:

Through hole

|

Schematics Diagrams

List of Part Numbers

| Part number | Shape of terminal | Circuit | Packaging form | Packaging quantity | Material data | CAD | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CS-4-12YTA | J-hook | 1 pole 2 contacts with neutral detent |

Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12YA | J-hook | 1 pole 2 contacts with neutral detent |

Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12XTA | J-hook | 1 pole 2 contacts without neutral detent | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12XA | J-hook | 1 pole 2 contacts without neutral detent | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-13NTA | J-hook | 1 pole 3 contacts | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-13NA | J-hook | 1 pole 3 contacts | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-14NTA | J-hook | 1 pole 4 contacts | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-14NA | J-hook | 1 pole 4 contacts | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-22YTA | J-hook | 2 poles 2 contacts with neutral detent |

Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-22YA | J-hook | 2 poles 2 contacts with neutral detent |

Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12YTB | Gull wing | 1 pole 2 contacts with neutral detent |

Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12YB | Gull wing | 1 pole 2 contacts with neutral detent |

Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12XTB | Gull wing | 1 pole 2 contacts without neutral detent | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12XB | Gull wing | 1 pole 2 contacts without neutral detent | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-13NTB | Gull wing | 1 pole 3 contacts | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-13NB | Gull wing | 1 pole 3 contacts | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-14NTB | Gull wing | 1 pole 4 contacts | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-14NB | Gull wing | 1 pole 4 contacts without neutral detent | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-22YTB | Gull wing | 2 poles 2 contacts without neutral detent | Taping | 500 pcs./reel |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-22YB | Gull wing | 2 poles 2 contacts without neutral detent | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12YC | Through hole | 1 pole 2 contacts with neutral detent |

Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

||||||||

| CS-4-12XC | Through hole | 1 pole 2 contacts without neutral detent | Bulk in plastic bag | 50 pcs./pack |

Downloadable chemSHERPA-AI files by selecting the latest ver. 2.11.00 or the previous ver. 2.10.00 from the following buttons. [Need to log in to download]

*

You can download the chemSHERPA Data (AI) Entry Support Tool for articles V2R1.01.0 (compatible with up to the latest data sheet ver. 2.11) from here.

|

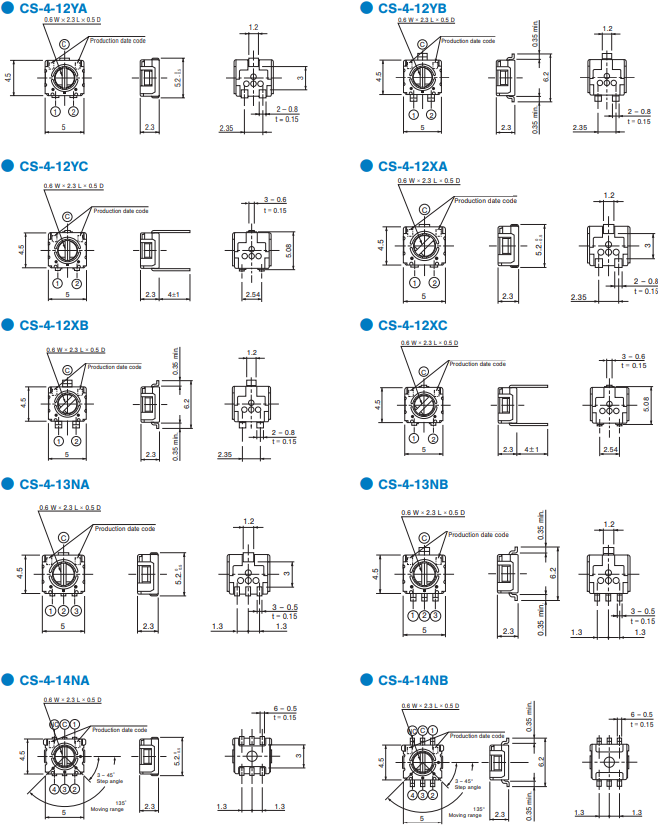

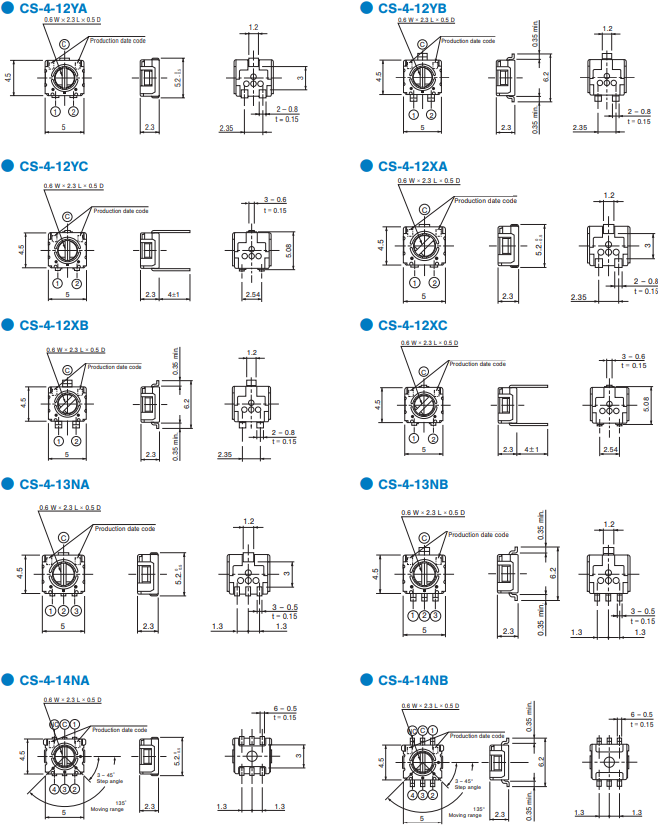

Outline Dimensions

Recommended P.C.B. Pad Outline Dimensions

Soldering Conditions

When dip-soldering CS-4-13NA, NB or CS-4-22YA, YB solder bridges may occur between terminals depending upon soldering conditions. In order to prevent such bridges,vertical flow direction is recommended as shown in the below figure. For dip-soldering,preheating should be done after applying flux.

Handle carefully in case of parallel flow direction in which solder bridges occur more often because solder flow moves toward the vertical direction against the terminals. In addition, other soldering conditions such as soldering temperature, preheating temperature, specific gravity of flux, and belt speed affect the occurrence of bridges.

Depending on flux to be applied, markings may, though at rare case, disappear or fade out at soldering. Please make sure before its use.

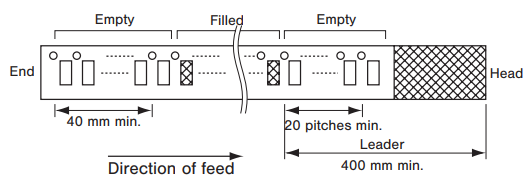

Packaging Specifications

〈Taping packaging specifications〉

-

●Embossed tape dimensions

-

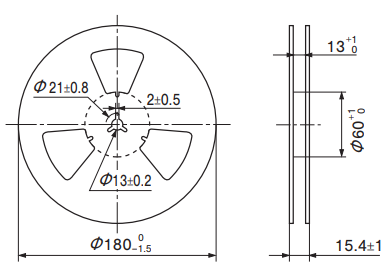

●Reel dimensions(Unit: mm)(Conforms to JIS C 0806-3 , In accordance with EIAJ ET-7200A)

-

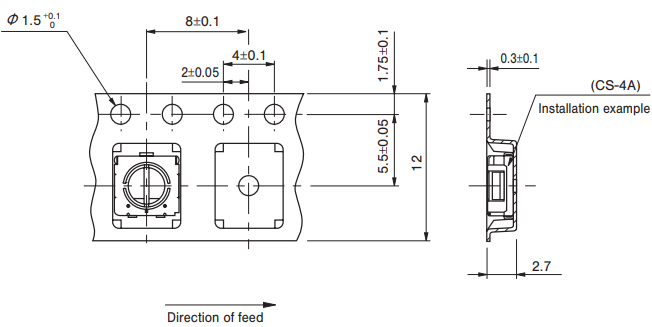

●CS-4-□□□TA / CS-4-□□□TB(Unit: mm)(Conforms to JIS C 0806)

〈Bulk pack specifications〉

Documents

- ●The above contents and descriptions are subject to change without notice.