Pressure Sensors Special Feature

Pressure Sensors Special Feature

- Chapter 1

- What is a pressure sensor?

1. Outline

- - Contents -

- 1. What is a pressure sensor?

- (1) Outline

- (2) Operating principles

- 2. Introduction of our pressure sensors

- (1) Milestones

- (2) Abundant standard product lineup

- 3. Strengths of our pressure sensors

- (1) In-house integrated production

- (2) Special products (Customizations)

- 4. FAQ about Pressure Sensors

- 5. Our pressure sensor series lineup

2. Operating principles

Pressure sensors generally use a diaphragm that formed strain gauges on, and measure its strain (or deflection) due to applied force over the diaphragm area.

Our company, NIDEC COMPONENTS offer two types of pressure sensors as sensing methods: a method using a diffusion type semiconductor (Silicone MEMS) and a method using a thin film gauge with SUS diaphragm. Each type has its own characteristics, and we have a wide variety of pressure sensor products by properly using these two type methods according to the application and market requirements.

Let's take a closer look at the operating principle for each type.

Ⅰ. Silicone MEMS (Si-MEMS)

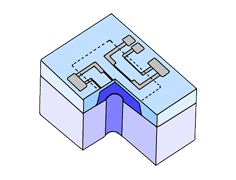

cross-section drawing

The four strain resistors, connected as shown in the schematic below, constitute a Wheatstone bridge circuit. This bridge circuit is driven by constant current (nominal 1.5 mA DC). When pressure is applied, the resistance values of R2/R3 increase while those of R1/R4 decrease, bringing about inequality in the bridge circuit and causing a voltage difference at the output end. This voltage difference turns into an output voltage proportional to the pressure. Even when negative pressure is applied, the polarities are also inverted to the same orientation as when a positive pressure is applied.

To explain the pressure and output characteristic, the deformation of the diaphragm is illustrated in a magnified manner in the diaphragm cross-section drawing on aboveright, but the degree of deformation is as so small as several micrometers. Therefore, the mechanical deformation of the diaphragm is hardly recognized in appearance.

Ⅱ. Thin film sensor (SUS diaphragm)

cross-section drawing

Ⅱ. Thin film sensor (with SUS diaphragm)

In a thin film sensor, as with Si-MEMS, four thin film resistors are connected as shown in the schematic below to constitute a Wheatstone bridge circuit. The thin film resistors are driven by constant voltage. The metal diaphragm deforms once it receives pressure, the thin film resistors formed on the diaphragm distort, which then detect any changes in the resistance value of the gauge. Thus, a voltage signal in proportion to the pressure can be obtained.

- Chapter 2

- Introduction of our pressure sensors

1. Milestones

We've been supplying pressure sensors for about 40 years, beginning with the manufacturing and sales of pressure sensors for electronic sphygmomanometers in 1980. Thanks to you, our pressure sensors are widely used in various industries such as semiconductor manufacturing equipment, industrial equipment, medical equipment, analysis equipment, measuring equipment, and hydraulic equipment such as machining centers.

Sano Plant satellite-photo

Sano Plant satellite-photo Sano R&D center

Sano R&D center

The business base will be the Sano Plant in Tochigi Prefecture, Japan. We handle everything from sensor chips to final pressure sensor products, and today it has grown into a leading business of our company.

2. Abundant standard product lineup

The types of pressure sensor elements are the semiconductor Si-MEMS and the thin film sensor with SUS. Among them, there are two types of Si-MEMS methods; one is a silicon single crystal type dedicated to non-corrosive gas as a medium, and the other is a dual diaphragm structure type that is placed a SUS diaphragm in the wetted part, that can also apply for liquids as a medium. We use each of these sensor elements appropriately according to the application and environment, and develop them into various final products.

| Method | Si-MEMS (Si single crystals) | Si-MEMS (Dual diaphragm) | Thin film sensor with SUS |

|---|---|---|---|

| Structure |  |

|

|

| Si single-crystal element is bonded to the glass base by means of anodic bonding via Na ions contained in the glass. The Si single-crystal element directly receives the medium. | An SUS diaphragm is bonded to the housing by means of laser welding, and conveys pressure to the silicone sensor chip via the silicone oil. | A thin film gauge is formed by means of vapor deposition on a SUS diaphragm via an insulating film. | |

| Media | Dedicated for noncorrosive gas | Gas or liquid that does not corrode the SUS material in the wetted part | Gas or liquid that does not corrode the SUS material in the wetted part |

| Features |

|

|

|

|

Our pressure sensor series lineup | |||

|

Pressure |

P-2000, P-3000S | P-8300, P-8305, P-8505 | ― |

|

Pressure |

PA-20, PA-100, PA-500 | P-7100, PA-750/758, PA-800, PA-830/838, PA-838-D, PA-850/858, PA-860/868 |

High vacuum: PA-920S/928S

High temperature: PA-930/930-A |

| Pressure switch | PS20, PS30, PS40, PS6, PS60 | PS8, PS83, PS85, PS86 | High vacuum: PS91, PAS91 |

|

PG-30, PG-200,PG-100N | PG-35, PG-35H, PG-75, PG-208, PG-100B | High vacuum: PG-20, PG-35L |

In recent years, we've been aggressively releasing new products such as types with a built-in small amplifier with ratiometric output and types for high vacuum and high temperature using the thin film sensor elements with SUS, and we are expanding our business domain.

- Chapter 3

- Strengths of our pressure sensors

1. In-house integrated production

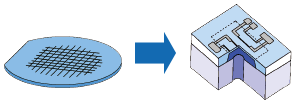

We manufacture in-house from sensor elements by making full use of semiconductor technology, and further develop and manufacture pressure sensor final products through processes such as mounting, temperature compensation, electronic circuit addition and casing, etc.

-

Silicone wafer ⇒ Sensor chip

Pressure sensor module

Pressure sensor products

with amp.

A major feature of our pressure sensor is that we handle everything from development design to sensor element manufacturing process and product assembly process / calibration under the integrated quality control of our pressure sensor business based on high-mix low-volume production. Our strength lies in this business structure, which is capable of responding to special specifications and various customer needs in detail.

2. Special products (Customizations)

― Policy for custom support ―

Our policy for customizations is as follows:

- If we can apply our existing products / technologies and judge that they can be commercialized in consideration of business feasibility, we will actively accept custom support.

- Even if the technology we have is scarce at the time of your request, we will consider it positively if we judge that joint development is possible.

- We will proactively propose the products and services that our customers need by collecting information by industry unique to us.

Our pressure sensors have a total of 92 models, and the P/N of models is 1,992. Of these, Customizations, so-called Special products, accounts for nearly 80% of the total on a monetary basis, and as the results show, we have provided many custom products and services that meet the individual needs of the market and customers. Introduce some examples of the special products bellow.

Customization examples

Electrolytic polishing + Degreasing + Clean packaging

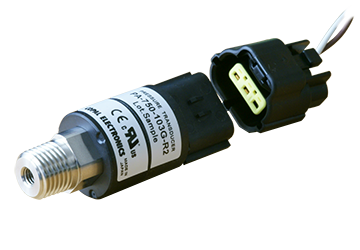

PA-750/758 series: Compatible with cable connectors and Direct cable from body

Standard model

Standard model

(1) Cable with connectors

(1) Cable with connectors (2) Direct cable from body

(2) Direct cable from body

The PA-750/758 standard series uses a connector cable that the body and cable can be attached and detached, and the cable tip has a lead wire. We have both achievements in supporting (1) the installation of designated tip connectors and (2) direct cable removal from the main unit.

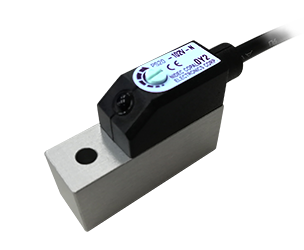

PS20 series: Special fitting

Standard model

Special fitting

Special fitting

The PS20 standard series is M5 male screw or block M5 female screw, but we have made a proposal to meet the market needs to extend the tip of the block, make an hole for M5 female screw, and fix it with a mounting screw.

Other examples

Specification / Performance change

| Pressure range / Pressure unit | Pressure range: Provision of range other than that in standard products, change of standard pressure unit (e.g. PSI, etc.) |

|---|---|

| Performance | Accuracy enhancement (e.g. output calibration error, improvement of temperature characteristic, improvement of pressure resistance, etc.) |

| Output | Analog output value, support for I2C/SPI, and others |

| Power voltage | Change to desired power voltage |

| Ambient temperature | Change to specification suitable for desired ambient temperature |

| Switch setting | Shipment with a desired pressure threshold setting |

| Zero adjustment | Addition of zero adjustment setting |

Appearance / shape change

| Fitting | Shape, size, material, etc. |

|---|---|

| Cable | Length, lead wire diameter, connector processing, terminal processing, tag attachment, etc. |

| OEM design | Name plate, panel design, casing color, etc. |

Others

| Custom development | Manufacturing of circuit board, unit design, custom-made shape, etc. |

|---|

With our experience and expertise, we will propose the best products and services that meet your needs. Please feel free to contact us from the button below.

- Chapter 4

- Pressure sensors FAQ

1. About Products

| 1. About cable specifications | |

|---|---|

| Q. We want to attach a connector to a cable. Where can we find your cable specifications? | Answer |

| 2. Scope of non-corrosive gases in medium | |

| Q. For use with P-2000 or P-3000S, you require a non-corrosive gas as the pressure medium. Can steam-laden air be used? If not, which model would you recommend? | Answer |

| 3. How to clear noises (Wiring shield cable) | |

| Q. The transducer that we use has a built-in amplifier. Its output fluctuates, and it appears that noise is the cause. The mounting side is insulated. The shielding wires on the receiver side are disconnected during use. What measures should be implemented? | Answer |

| 4. How to set switch of pressure switch | |

| Q. We plan to use a KF25 flange fitting with a PS91 vacuum switch to monitor atmospheric pressure and detect when a vacuum heating oven is under atmospheric pressure. We are unsure how to select N1 and N2 and would appreciate your advice. We imagine that the vacuum switch turns on when the pressure returns from a vacuum to atmospheric pressure. How should the switch output be set so that the vacuum switch turns on at -80 kPa as the pressure changes from atmospheric to a vacuum? | Answer |

| 5. Mounting on PCB (Manual soldering required) | |

| Q. We want to solder a P-2000 onto a printed circuit board. What are your recommended soldering conditions? | Answer |

| 6. Recommended fittings for M5 female screws connecting tubes | |

| Q. We want to connect a pressure sensor to its tube using an M5 female screw. What attachment do you recommend? | Answer |

| 7. Recommended tubes for quick fittings | |

| Q. What tubes do you recommend for use with the quick fittings? | Answer |

| 8. How to installate to piping (Tightening torque) | |

| Q. What tightening torques do you recommend for tapered screw types? | Answer |

| 9. ffect of vertical to horizontal installation position | |

| Q. The dual-diaphragm pressure sensor we use varies in output depending on whether the pressure port is turned downward or sideways. Does this mean the sensor is out of order? | Answer |

| 10. Stability after power applied | |

| Q. According to the Common Notes, a warm-up time of about 10 minutes after power-on allows more accurate measurement. How much does the output voltage [V] fluctuate during the 10 minutes after power-on? We also want to know whether the output voltage changes linearly or not. | Answer |

| 11. Products selection suitable for using high vacuum | |

| Q. We introduced the PA-850-102A-NR2 to monitor the pressure inside the vacuum chamber. Our process requires reducing the pressure to an absolute pressure of approximately 0 kPa. However, the brochure specifies an operating vacuum lower limit of 1.3 kPa abs. Why is it unusable beyond this value? Please recommend pressure sensors that can be used beyond this value. | Answer |

| 12. About operating temperature range of medium | |

| Q. What is the liquid temperature range applicable to the PG-35? Although we are currently using room-temperature water, we want to use heated water and hence have to know the liquid temperature range. | Answer |

| 13. Effect of accuracies by ambient temperature | |

| Q. How come the PG-100B has two different system accuracies, one being ±0.5%F.S. ±2 digits and the other being ±1.0%F.S. ±2 digits? Besides, what does "±2 digits" mean? | Answer |

| 14. Rated pressure range / Max. pressure / Break pressure | |

| Q. What does the rated pressure range and maximum pressure in the specification mean? Will the sensor be broken if the burst pressure value is exceeded? | Answer |

| 15. How to purchase lithium batteries for PG-100 | |

| Q. The replacement battery specified for the PG-100 manometer is a 3.6 VDC lithium battery. The battery originally supplied with the PG-100 is manufactured by Toshiba and bears the model number ER6VM/3.6. This model cannot be found on Toshiba's website, though the ER6V P3.6 model can. Would it be okay to use the latter instead? | Answer |

| 16. Product lineup in accordance with UL991 | |

| Q. We are considering using a pressure sensor for a semiconductor manufacturing machine. Are UL991-compliant ones available from you? | Answer |

| 17. How to solve E2 ERRORs in pressure gauges | |

| Q. We restarted a PG-75 for the first time after long-term non-use. Its zero adjustment resulted in an "E2 Error" message. How should this be dealt with? | Answer |

| 18. Effects of the use of not specified power supplies | |

| Q. According to its specifications, the P-3000S operates with a standard constant current of 1.5 mA. Would there be any problems if it were driven with a constant voltage of 5 V? Additionally, how will the accuracy of linearity and the temperature characteristics be affected if a 1 mA current is set for constant current drive? | Answer |

| 19. How to solve Zero Point ERRORs in pressure gauges | |

| Q. The PG-100 handy manometer we use reads "-00.3" at power-on. The normal reading should be either "00.0" or "00.1." Is our PG-100 out of order? | Answer |

| 20. Batteries replacement notice of Manometers | |

| Q. Is it normal that the reading by the PG-100 manometer appears thin when its battery is running low? Does a dying battery result in a reading lower than the actual pressure? Is there any method we can check with as the reference for the time to replace the battery? | Answer |

| 21. About elements and materials of pressure sensors | |

| Q. We have adopted the PG-35 pressure gauge as the atmospheric pressure detector for our vacuum equipment. The specifications for an end user who has inquired about our vacuum equipment require that the atmospheric pressure sensor be a semiconductor sensor with a stainless steel diaphragm. Does the PG-35 meet this requirement? | Answer |

| 22. Manometers selection for organic solvent medium | |

| Q. We want to use a PG-100-102A at hand to measure a fluid containing a diluted organic solvent. Is this possible? | Answer |

| 23. Use at high altitudes / Kind of pressure references | |

| Q. We are considering using a PS6-102G-NAR at an altitude of 1,000 meters. Would this be possible? | Answer |

| 24. Out of Production | |

| Q. What is the discontinuation information for the pressure sensor? | Answer |

| 25. How to operate the settings of Pressure gauge PG-30/PG-35? | |

| Q. Could you please explain how to set up and operate the PG-35L pressure gauge? Is there explanatory material that beginners can understand? | Answer |

2. Documents and Certificates

| 26. How to obtain certificates of non-applicability | |

|---|---|

| Q. We need a certificate of non-applicability to export a single product to a customer overseas. How can we obtain a certificate of non-applicability? | Answer |

| 27. How to get CAD data | |

| Q. Can we get 2D/3D CAD data of your products? | Answer |

| 28. How to obtain declaration of CE conformity | |

| Q. How can we get the declaration of CE conformity of your pressure sensor? | Answer |

| 29. How to obtain ISO9001 / 14001 certificates | |

| Q. We understand you are an ISO 9001/14001 certified company. Can we obtain a copy of your certificate? | Answer |

| 30. About failure rates of products | |

| Q. We would like to know the failure rates of your products. Could you provide us with the failure rate data? | Answer |

| 31. How to obtain RoHS3 compliant certificates | |

| Q. Are your products compliant with RoHS Directive (EU) 2015/863? | Answer |

| 32. How to obtain UL certificates | |

| Q. Our product requires a safety review for which we need a UL certificate for your product. May we obtain a copy of this certificate? | Answer |

3. Maintenance and Calibration

| 33. Models for calibratable services / How to obtain the certificates | |

|---|---|

| Q. We use a PG-100B. Do you offer calibration services for this model? | Answer |

| 34. Investigation of faults / Repair / Replacement | |

| Q. After powering on, the PG-100 displays "-1." This reading does not change even under pressure. Do you know what causes this? Can this issue be resolved? | Answer |