Rotary encoders RE12

Small size, high resolution and low cost

- φ 12 mm, High resolution up to 300 P/R

- Cost effective

- Two bearing types to choose from;

Sleeve bearing or ball bearing - Low torque, low inertia

- RoHS compliant

PART NUMBER DESIGNATION

| RE12 | A- | 100- | 100- | 1 |

|---|---|---|---|---|

|

Series name |

Bearing A: Ball bearing C: Sleeve bearing |

Resolution (P/R) 100, 200, 300 |

Output phase:“A” Input voltage : 5 V No AMP |

Output connection 1: Cable wire |

LIST OF PART NUMBERS

| Part number | Bearing | Resolution | CAD |

|---|---|---|---|

| RE12A-100-100-1 | Ball Bearing | 100 P/R |

|

| RE12A-200-100-1 | Ball Bearing | 200 P/R | |

| RE12A-300-100-1 | Ball Bearing | 300 P/R | |

| RE12C-100-100-1 | Sleeve Bearing | 100 P/R | |

| RE12C-200-100-1 | Sleeve Bearing | 200 P/R | |

| RE12C-300-100-1 | Sleeve Bearing | 300 P/R |

ELECTRICAL CHARACTERISTICS

| Resolution | 100・200 P/R | 300 P/R |

|---|---|---|

| Photo-sensor maximum current | 50 mA maximum (at 25 °C) | |

| Output wave form | Quasi-sinusoidal | |

| Output signal ※1 | 150 mVp-p minimum | 100 mVp-p minimum |

| Output signal amplitude variation ※2 |

40 % maximum | 50 % maximum |

| Light source | LED | |

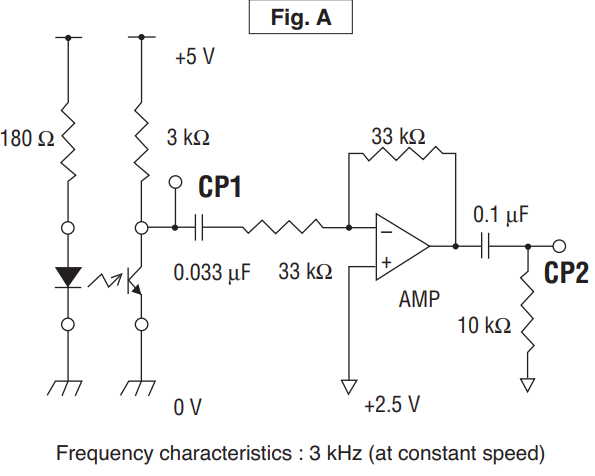

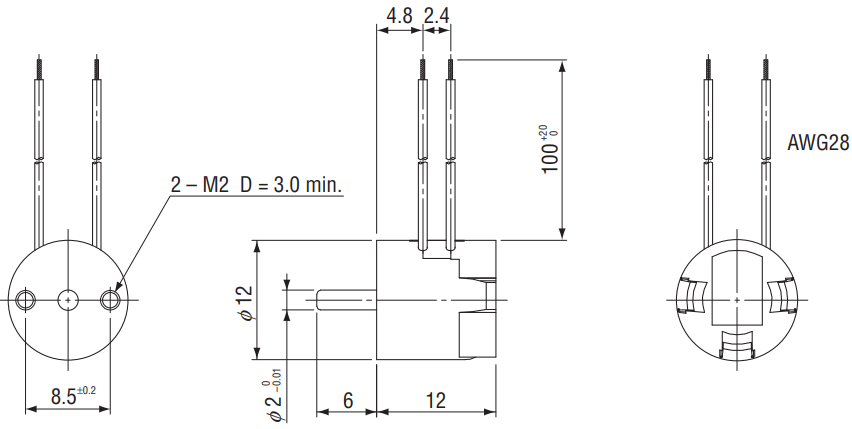

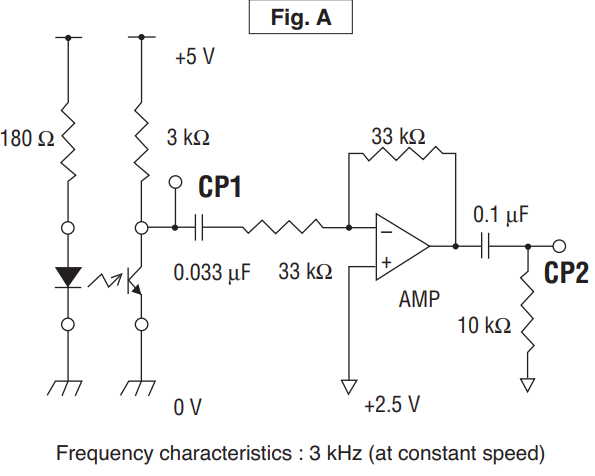

※1:Measured at CP1 as per the Fig. A of ‘MEASUREMENT CIRCUIT’ on the following page. (3 kHz)

※2 : Measured at CP2 as per the Fig. A of ‘MEASUREMENT CIRCUIT’ on the following page. (3 kHz)

⦿MEASUREMENT CIRCUIT

Mechanical characteristics

| Starting torque | Ball bearing | 0.05 mN·m {0.5 gf·cm} maximum | |

|---|---|---|---|

| Sleeve bearing | 0.4 mN·m {4 gf·cm} maximum | ||

| Inertia | 0.01 g·cm2 maximum | ||

| Shaft loading | Radial | 1.96 N {200 gf} maximum | |

| Axial | 4.9 N {500 gf} maximum | ||

| Net weight | Approx. 10 g | ||

Environmental characteristics

| Operating temp. range | - 10 ~ 50 °C |

|---|---|

| Storage temp.range | - 20 ~ 80 °C |

| Protection grade | IP40 |

Output signal level & Amplitude variation

⦿ Criteria

| 項目 | 100・200 P/R | 300 P/R | Measurement point |

|---|---|---|---|

| Output signal level | S min ≧ 0.13 V | S min ≧ 0.08 V | CP1 in ‘MEASUREMENT CIRCUIT’ |

| Amplitude variation | (S max / S min – 1) × 100 ≦ 45 % | (S max / S min - 1) × 100 ≦ 55 % | CP2 in ‘MEASUREMENT CIRCUIT’ |

⦿ MEASUREMENT CIRCUIT

RELIABILITY TEST

| Test item | Test conditions | ||

|---|---|---|---|

| Vibration | Power OFF | Amplitude : 1.52 mm or 98.1 m/s2 (10 G) whichever is smaller. 10 ~ 500 Hz excursion 5 min/cycle, 1 hour each for X, Y, Z, directions. |

|

| Shock | Power OFF | 1 time each in 6 directions (X, Y, Z) at 490 m/s2 (50 G), 11 ms. | |

| High temperature exposure | Power OFF | 80 °C 96 h | (To be measured after leaving samples for 1 h at normal temperature and humidity after the test.) |

| Power ON | 50 °C 96 h | ||

| Low temperature exposure | Power OFF | - 20 °C 96 h | |

| Power ON | - 10 °C 96 h | ||

| Humidity | Power OFF | 40 °C Relative humidity 90 ~ 95 % 96 h (To be measured after wiping out moisture and leaving samples for 1 h at normal temperature and humidity after the test.) |

|

| Thermal shock | Power OFF | To be done 10 cycles with the following condition (To be measured after leaving samples for 1 h at normal temperature and humidity after the test.) 80 °C 1 h、-20 °C 1 h |

|

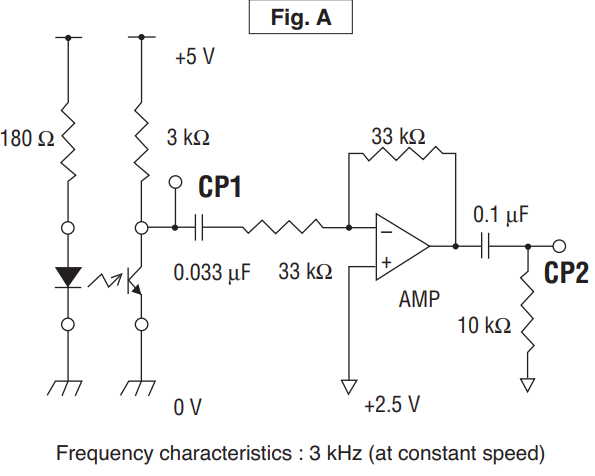

OUTLINE DIMENSIONS

Unless otherwise specified, tolerance : ± 0.4 (Unit : mm)

INTERNAL CIRCUIT

MEASUREMENT CIRCUIT

Documents

- ●The above contents and descriptions are subject to change without notice.